How would you make better coatings for medical implants? Sushi!

They say opposites attract.

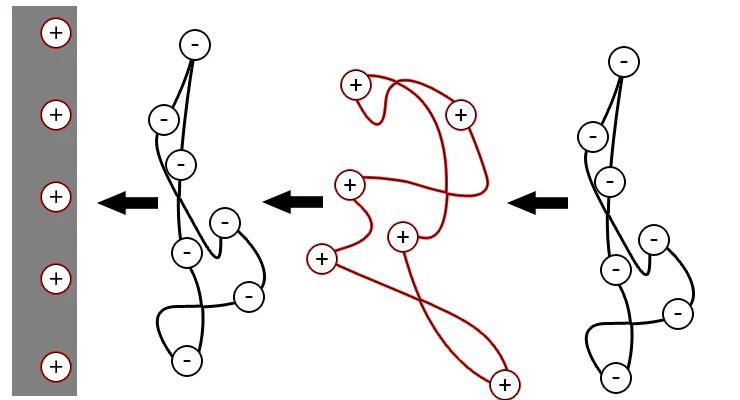

But this isn’t just a romantic phrase. Materials scientists have long used layers of oppositely charged chemical compounds to create coated surfaces with desirable properties for various applications: biomedical implants, engineered bone tissue, “anti-stick” medical devices – you name it. This sandwiching of oppositely charged compounds into films that stack up on a surface, known as polyelectrolyte multilayers or PEMs, can be accomplished with natural compounds such as fucoidans, sugar polymers found in species of brown algae and brown seaweed. Such natural compounds result in biocompatible PEMs that can be used inside the human body, and that may even naturally resist microbial build-up on coated surfaces.

Opposites Attract. Schematic showing the alternating adsorption of positively and negatively charged polyelectrolytes to a solid surface. Created by Ayouril, Wikipedia.

PEMs are a highly interesting (albeit highly technical) area of science with an extensive array of industry applications, including coatings on medical devices. PEMs that are comprised of materials from natural origin are desirable, especially if those materials can also deliver health benefits to target sites. Fucoidans offer great potential to do this, due to being antibacterial, antiviral, antifouling and resistant to degradation by mammalian enzymes. – Marinova, a manufacturer of fucoidan extracts

A group of Australian researchers recently published a paper in ACS Langmuir describing the the formation and hydration of a Fucoidan/Chitosan PEMs. They wanted to determine the amount of hydration and other properties in PEMs created with fucoidans extracted from different types of seaweed. Why? Because how much a surface “likes” or “hates” water is an important property when we consider putting that surface in various environments including inside the human body.

For example, at the microscopic level (actually, even smaller than most microscopes can see), is the surface coating of your hip implant rough, sticky or smooth? You’d want to know the answer to that before choosing a given implant surface coating. And how many layers of a given fucoidan PEM do you need before you reach a desired level of water-loving or water-hating?

“In their potential applications as lubricants and drug storage or release vehicles, the environment inside the (PEM) coating is thought to be important,” study author David Beattie said. "If it is only slightly hydrated and hydrophobic then it may not act as an effective lubricant, and it will only allow you to store certain drug molecules (normally ones with poor solubility). If it is well hydrated (and thus hydrophilic), it should act as a better biolubricant, and it would allow you to load it up with water-soluble drugs."

Using a special type of infrared light microscopy, David Beattie and colleagues assessed the properties of PEMs made with two different kinds of fucoidans. In fact, the group developed a process of analyzing properties of PEMs that allows other researchers to better customize such coatings for targeted features.

In a follow-up paper, the group was able to determine that PEMs made with a fucoidan extracted from Fucus vesiculosus or the bladderwrack seaweed are thicker and rougher (and more hydrated) than PEMs made with fucoidan extracted from Undaria pinnatifida. The later is also known as Wakame, an edible seaweed you might have enjoyed on a salad at your local sushi restaurant.

“Different species of seaweed give subtle variations to the fucoidans that can be extracted from them,” Beattie said. “We're not sure if the 'goldilocks' nature of the hydration amount will prove useful for applications - but we at least know how to control that aspect of the coating.”

So next time you eat sushi (on a romantic date, perhaps), think of how opposites attract, and how compounds extracted from your seaweed salad might produce better biolubricants for catheter coatings or smoother coatings on another medical device some day.

This blog post was written for a backer of my recent SciBlogReaders Experiment.com project. Cross-posted at scilogs.com/from_the_lab_bench.